Vapor Phase Cleaning and Vapor Phase Decontamination

Vapor Phase Cleaning & Decontamination Products

Our JPX line contains powerful water-based and non-hazardous products formulated for vapor phase decontamination and cleaning as well as other refinery, petrochemical, and industrial cleaning applications. Our cleaning solutions are cost-effective and proven to outperform other well-known but significantly more expensive products. JPX has been utilized in numerous turnarounds and shutdowns. It is highly effective at low concentrations. Additionally, it is biodegradable and compatible with most surfaces.

- JPX Vapor Phase Decontamination Cleaner: A powerful cleaner that removes hydrocarbons and other contaminants.

- JPX-E for Cleaning Sour Equipment (H₂S): Use this formula for hydrocarbons and for complete H2S removal. JPX-E is a biodegradable degreaser that handles the toughest cleaning jobs.

- JPX-EE Neutralizes Pyrophoric Materials: Solubilizes and oxidizes pyrophoric materials, use this product in the decontamination and cleaning process as a pyrophoric remover.

Jayne Products also offers Refinery Planning & Services, as well as Petrochemical Services and Planning.

JPX Product Line Benefits

- Refinery Top rated in heavy oil degreasing, emulsification, and being low in toxicity with minimal effluent impact

- After decontamination process, waste streams can be broken into layers for hydrocarbon recovery

- Powerful water-based product

- Reduces time compared to traditional steam only purging

- Biodegradable

- Non-Caustic, Non-corrosive and compatible with all metals

- Significantly reduces time to reach acceptable Benzene, Hydrogen Sulfide and LEL levels

- Excellent with foamers and stable foam for vertical cling

- Easy to use application

- Superior Emulsification of 40%

- FeS Oxidized

- 0 PPM LEL

- 0 PPM H²S

- 0 Pyrophorics

- 0 PPM Benzene

Vapor Phase Decontamination & Cleaning Advantages

Vapor phase decontamination, vapor phase cleaning, or degassing with JPX will:

- Cut steam out time by 2/3, much less downtime

- Greatly reduce mechanical cleaning required prior to inspection or repair

- Decontaminates that can’t be contacted by a liquid circulation

- Allows for continuous injection of fresh chemical and hydrocarbon level monitoring

- Safe for people, the effluent system, and air quality

- Amount of product used reduced, leading to less waste

- The energy needed to maintain the temperature of solution reduced

- Procedures and applications are consistent and verifiable, reducing the risk of further downtime

- Preparation and maintenance activity time reduced

What is Vapor Phase Cleaning and Decontamination?

Vapor phase decontamination, also known as vapor phase cleaning and degassing, is the use of steam and cleaning or decontamination solutions to target contaminants such as hydrocarbons in process equipment including vessels, columns, heat exchangers, storage tanks, piping, reactors, etc. The purpose of decontamination is to remove hydrocarbons, LELs and benzene, pyrophorics, hydrogen sulfide, ammonia, and mercaptans to allow for quick and safe entry for maintenance, hot work, and inspection.

System and equipment decontamination in the past used only steam which took much more time and money, making it an inefficient and costly option due to the amount of steam and downtime. In addition, steam only did not have any effect on any pyrophoric iron sulfide deposits.

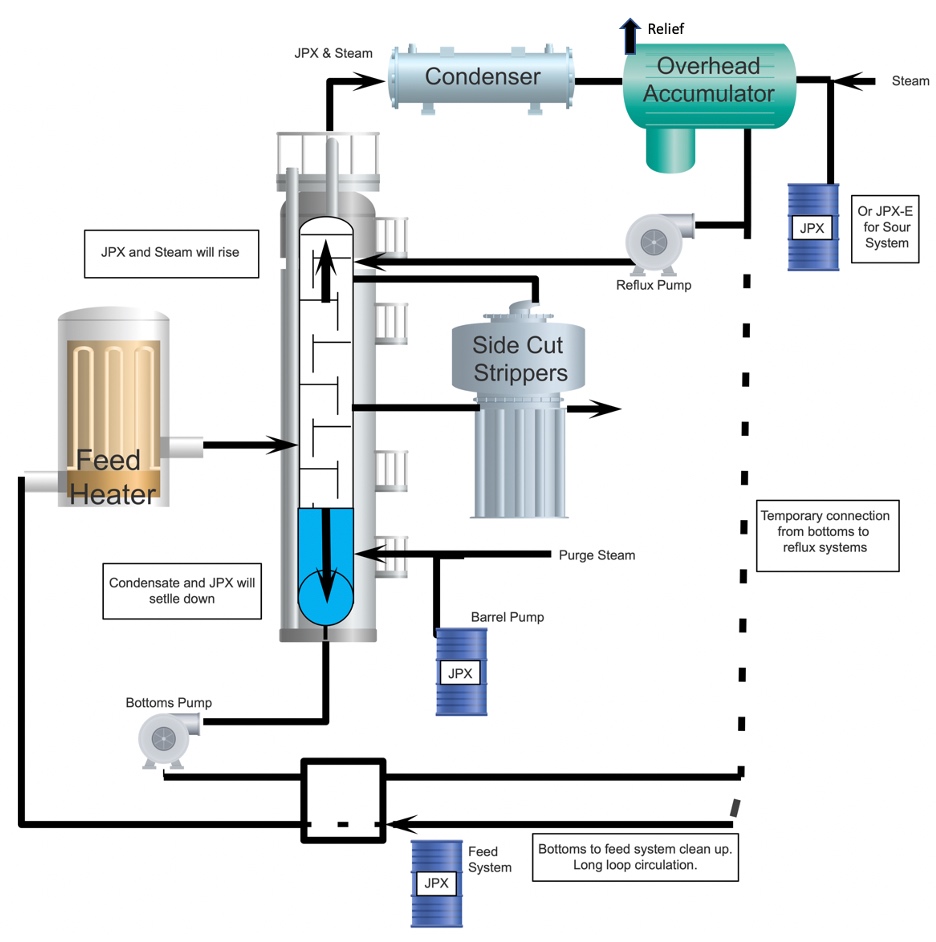

Vapor phase decontamination and cleaning allow the solution to be carried throughout the entire system with minimal injection points.

JPX Videos and Demos

- View our online demonstration of one of our oil refinery shutdown procedures - Vapor Phase Cleaning / Vapor Phase Decontamination

- View our JPX Set Up and Use Video

Vapor Phase Decontamination and Cleaning Procedure

- JPX begins working when it is pumped into a saturated steam source-typically medium pressure. The steam carries the JPX throughout the equipment.

- The solvent in the product vaporizes, this action sweeps the light hydrocarbons to the relief system.

- The heavier contaminates form an emulsion with the oil and steam condensate. This emulsion is drained intermittently during the process and fully at the end of the process.

- After the process is finished the steam is stopped and the equipment is water rinsed to cool down and prepare for personnel entry. The oil will rapidly separate from the emulsion for recovery.

Learn More About Our Safe and Effective Vapor Phase Decontamination Products

Our vapor phase cleaning and vapor phase decontamination products are proven to be highly effective cleaning and decontaminating agents. JPX is also used as a crude oil tank cleaning chemical to clean sludge for oil recovery, neutralize hydrogen sulfide (JPX-E), or pyrophoric removal (JPX-EE).

Our products won’t damage surfaces and are a safer, more eco-friendly alternative to other, harsher products on the market. See why our customers trust and value what we offer on our JPX reviews page.

For more information about our company and products, follow our Blogs, Youtube, and Linkedin.

Contact us to discuss your refinery decontamination application or request a quote for the JPX formula that meets your requirements.